Manufactures

For the purpose of providing the best products, ORIVER consecutively improves technology and introduces the most advanced automatic precision production equipment, so as to realize stable quality and increased capacity. Besides, we pay more attention to production process management, and possess a strong team and skilled techniques to serve you.

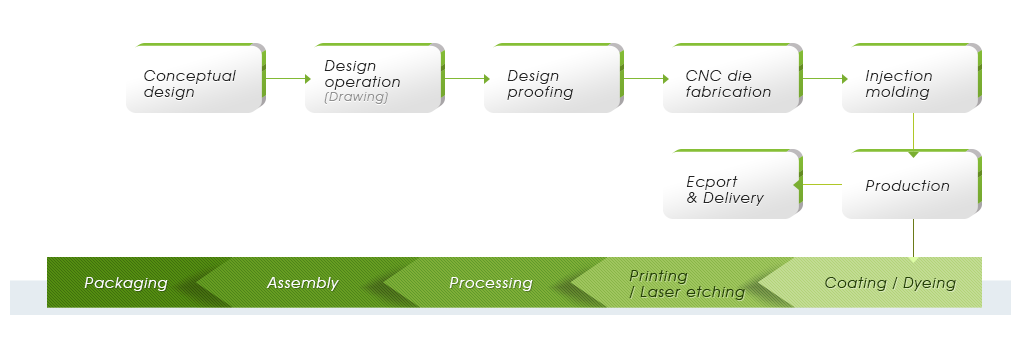

Through elaborative planning of many years, ORIVER has built a complete one-stop operation system. The whole production process, including various processing operations, is included in our own production lines, and no operation is commissioned to others. Therefore, we can ensure the best product quality based on our complete quality control system.

Through the whole production process, standard tools and measuring instruments are used to inspect the products. Precision testing equipment is employed to measure focal distance, prismatic power, astigmatism, stress, penetration, uv, etc, so as to ensure both the process and the products are within the set range of acceptable quality. The entire process, from material feeding, production to delivery, is supervised by QC personnel, so as to reduce the occurrence of rejects.

In the entire process of manufacturing, each step is strictly controlled for perfect quality. It is firmly believed that ORIVER can produce products satisfying customers based on ardent, quick and responsible service.

ORIVER keeps on improving production equipment and employing the most advanced machinery, not only ensuring the standardization of production quality, but also paying attention to the scale of production. Therefore, we are quite confident in the delivery time of customer’s orders, able to finish any task entrusted by our customers.

We emphasize quality control, able to reduce the cost of production and the number of defective products. All production wastes are recyclable, reducing damages to the earth. Based on the control of cost, we can offer preferential prices for our customers.